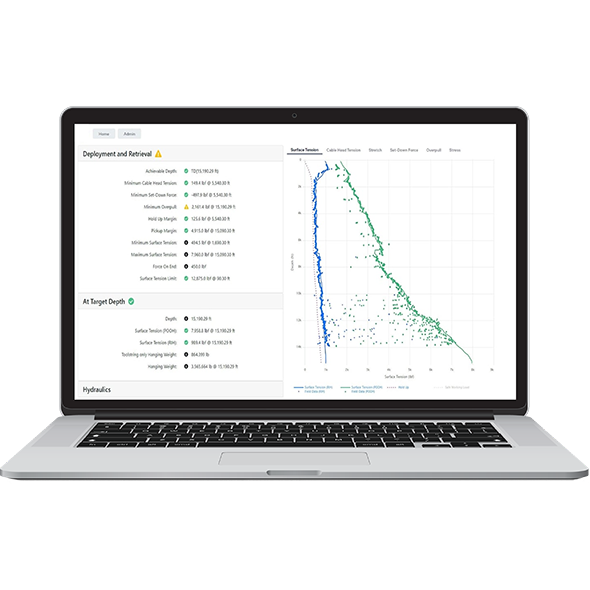

SMART Planner

Identifies risk and risk reduction strategies

Applications

- Toolstring design

- Wire selection

- Jar settings

Features and Benefits

- Calculate the best setting for an openhole or cased-hole wireline jar to avoid accidental firing

- Ensure the jar will fire before maximum pull at surface is reached

- Determine Roller Bogie® and I-Wheel® tool placement to reduce frictional forces

Tool Description

As an integral part of the Weatherford wireline product solutions, pre-job modelling provides the service company and operator with insights into optimum toolstring design, wire selection, and other operational fundamentals.

The results of pre-job modelling such as availability of overpull at target depth can be used to calculate the best setting for an openhole or cased-hole wireline jar to avoid accidental firing when pulling out of the hole but ensure the jar will fire before the maximum pull at the surface is reached.

Weatherford has conducted in-house testing to measure the friction reduction capabilities of our Roller Bogie and I-Wheel tools when strategically placed along any wireline toolstring. When the results of these tests are combined with the ability to reduce the resistive frictional forces of independent tools in a computer model, the output clearly demonstrates and quantifies the benefits of roller systems

Reach out to optimize reservoir performance

Please fill in the form below for more information on our comprehensive and high-resolution technologies. You will hear from one of our wireline representatives shortly.

Thank you for contacting us.

Your request is being directed to the appropriate person in our organization.

We will be in touch soon.