UltraView® Tool

Provides high-resolution ultrasonic measurements for accurate evaluation of casing and cement integrity

Applications

- Casing inspection

- Monitoring internal wear and corrosion

- Locating internal and external defects

- Measuring thickness

- Cement evaluation

- Measuring acoustic impedance

- Evaluating circumferential distribution

- Identifying location and orientation of channels and voids

Features and Benefits

- The UltraView tool can be run on either single- or seven-conductor wireline cables to maximize operational versatility.

- The patented mud chamber allows for real-time analysis of borehole fluid velocity, impedance, and density. Its design eliminates uncertainty in fluid properties measured during the down pass, which may not represent conditions while logging up.

- Variable head speed optimizes performance in heavy, viscous borehole fluids.

- High-resolution wellbore imaging provides detailed images of internal casing corrosion, defects, and perforation patterns.

- Consistent transducer firing minimizes the chances of overlooking important features. The result is a more accurate depiction of cement distribution around the casing.

- Multiple transducer frequencies expand casing-thickness measurement capabilities.

- Multiple centralization options address a wide range of casing sizes and various borehole geometries.

- Combinability with the Weatherford SecureView® suite, including CalView®, FluxView® and BondView® tools, enables diagnosis of multiple downhole threats in a single logging pass.

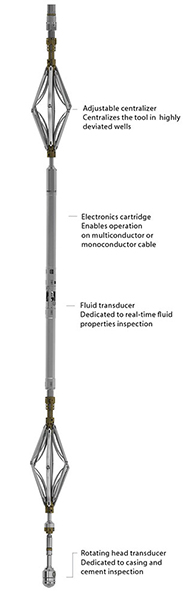

Tool Description

The Weatherford UltraView tool provides high-resolution data for accurate evaluation of cement, casing wear, casing thickness, corrosion imaging, and fluid properties. The tool uses two ultrasonic transducers. The primary transducer is dedicated to casing and cement inspection and is located in the rotating scanning head. This feature provides 360° circumferential coverage by capturing 72 samples per revolution.

The second transducer continuously measures borehole fluid properties and is located in the tool body. The fluid property measurements include real-time acoustic velocity, impedance, and density of the wellbore fluid.

The tool incorporates an advanced, high-speed, measure-on-position DC motor that rotates the primary measurement transducer. This transducer fires upon arriving at a precise point in its rotation, which ensures accurate circumferential depiction of casing defects and cement distribution.

Specifications

Measurement

Data | Acoustic impedance, fluid impedance, travel time, amplitude, casing ID, casing thickness |

Logging speed | 1,800 ft/hr (540 m/hr) |

Measurement range | Casing thickness: 0.200 to 0.800 in. (5 to 21 mm)* |

Vertical resolution | Cement evaluation mode: 1.0 in. at 1,800 ft/hr (540 m/hr) |

Thickness resolution | ±0.002 in. (0.051 mm) |

Acoustic impedance resolution | 0.2 Mrayl |

Accuracy | Internal radius: ±1% (FS) |

Depth of investigation | Thickness of casing; casing-to-cement interface |

Borehole fluids | Water-based fluids up to 15 lb/gal maximum mud weight** |

* The second harmonic is used for thicknesses greater than 0.69 in. (18 mm).

** Maximum mud weights are for combined casing and cement evaluation and will be dependent upon casing and transducer characteristics. Some applications may be possible at higher mud weights under certain wellbore conditions.

Mechanical

Outer diameter | 3.38 in. (86.0 mm)* |

Length | 18.66 ft (5.69 m) |

Weight | 315.00 lb (142.90 kg) |

Maximum temperature | 350°F (177°C)** |

Maximum pressure | 20,000 psi (138 MPa)** |

Minimum casing size | 4.5 in. (11.43 cm) |

Maximum casing size | 20.0 in. (50.8 cm) |

* Outer diameter depends on the scanning head used.

** Temperature and pressure ratings are 175°F (80°C) and 5,000 psi (35 MPa) when logging casing with an OD greater than 14 in.

Scanning Head*

Type | Diameter | Effective Radius |

A | 3.38 in. (8.59 cm) | 0.72 in. (1.83 cm) |

B | 3.13 in. (7.95 cm) | 1.28 in. (3.25 cm) |

C | 4.34 in. (11.02 cm) | 1.97 in. (5.00 cm) |

D | 5.44 in. (13.82 cm) | 2.56 in. (6.50 cm) |

E | 7.00 in. (17.78 cm) | 3.41 in. (8.66 cm) |

F | 8.71 in. (22.12 cm) | 4.25 in. (10.80 cm) |

G | 10.50 in. (26.67 cm) | 4.89 in. (12.40 cm) |

* Scanning heads are selected based on casing size and weight, transducer frequency, and the desired standoff distance between the transducer and inner casing wall.

Fluid

Transducer Frequency | Maximum Fluid Density | |

Water-Based Fluids** | Oil-Based Fluids** | |

250 kHz | 15.0 lb/gal (1,797 kg/m3) | 13.5 lb/gal (1,618 kg/m3) |

400 kHz | 13.8 lb/gal (1,654 kg/m3) | 11.5 lb/gal (1,378 kg/m3) |

600 kHz | 13.0 lb/gal (1,558 kg/m3) | 10.8 lb/gal (1,294 kg/m3) |

* Maximum mud weights are for combined cement and casing evaluation and will be dependent upon casing and transducer characteristics.

** Some applications may be possible at higher mud weights under certain wellbore conditions.

The UltraView tool simultaneously delivers data for internal and external casing inspection, cement inspection, and fluid properties analysis.

Log Presentation

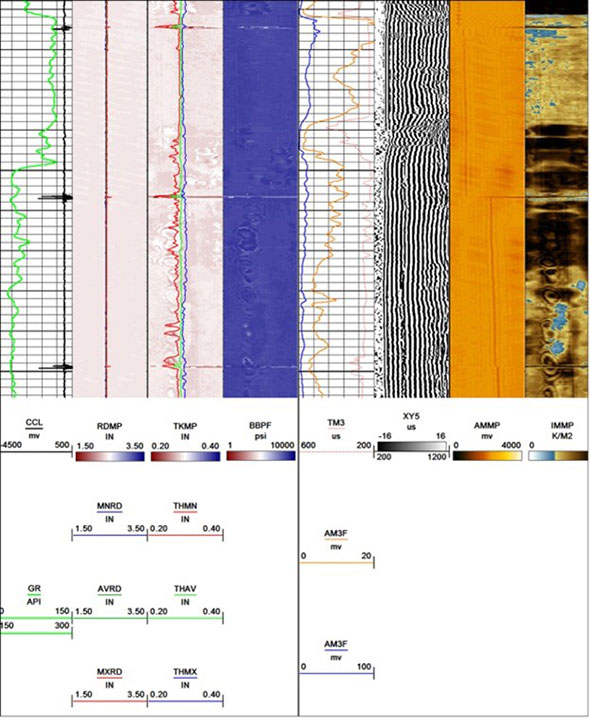

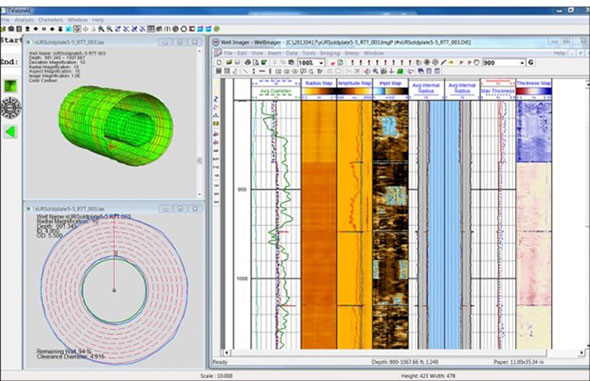

The UltraView tool delivers a comprehensive evaluation of casing, cement, and borehole fluid measurements. On the left is a log presentation from UltraView measurements. On the right, the same measurements from UltraView are used to generate interactive 2D and 3D images.

Reach out to optimize reservoir performance

Please fill in the form below for more information on our comprehensive and high-resolution technologies. You will hear from one of our wireline representatives shortly.

Thank you for contacting us.

Your request is being directed to the appropriate person in our organization.

We will be in touch soon.