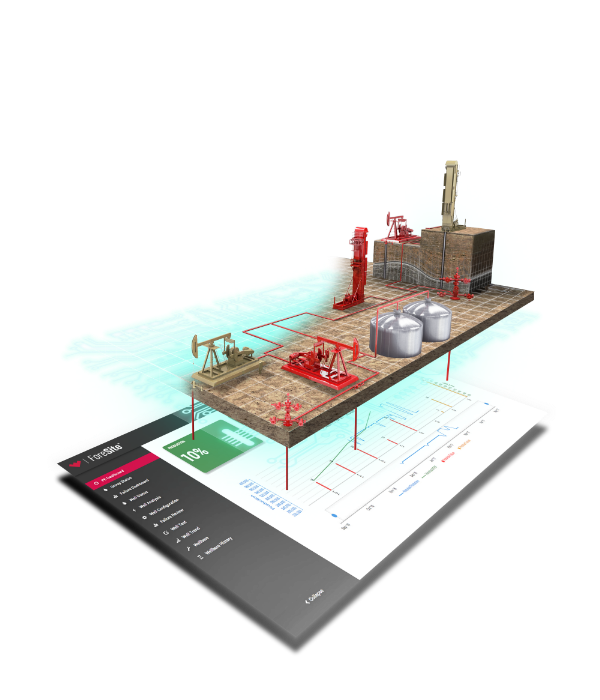

Production 4.0

Integrated Production Performance

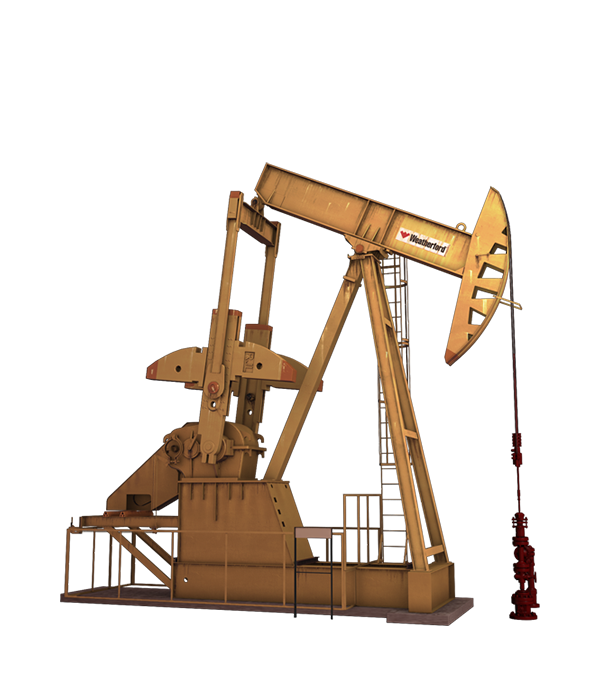

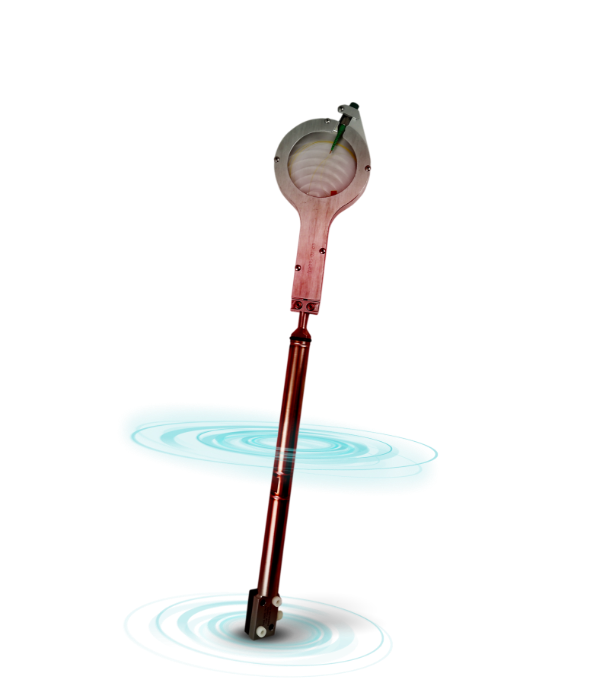

ForeSite Production 4.0 safely and systematically enhances production, maximizes uptime, and improves efficiency at the well and asset level. With unprecedented, real-time data integration from every corner of your business—including all downhole sensors, lift monitoring, and control systems—you can reap continuous and sustained efficiency gains for the life of every producing asset.