Raptor™ 2.0 Cased-Hole Evaluation System

Reveals bypassed reserves with accurate through-casing reservoir characterization

Applications

- Quantifying formation oil-water, gas-liquid, and water saturations though casing

- Pinpointing fluid contacts

- Classifying hydrocarbon types

- Monitoring changes in the reservoir during production

- Locating bypassed reserves in mature wells

- Characterizing pressure-depleted zones

- Distinguishing between gas and tight zones

- Assessing enhanced-oil-recovery (EOR) performance

- Identifying producible gas in thin beds

Features and Benefits

- Four spectroscopy sensors increase the gas-saturation measurement sensitivity by about 250% compared to traditional two-detector tools and provide dimensional oil-saturation measurements.

- Lanthanum-bromide (LaBr3) scintillators provide 3 times greater peak resolution for spectral analysis compared to bismuth-germanate (BGO) scintillators; 10 times brighter light output for improved signal-to-noise ratio compared to gadolinium-orthosilicate (GSO) scintillators; and 30 times better temperature stability compared to BGO scintillation detectors.

- A fast-neutron counter measures the precise neutron-emission rate from the pulsed neutron generator, which improves logging quality control, data timing accuracy, and response characterization.

- The T-100 calibrator offers a multipoint oil and gas sensitivity calibration, which provides factory-spec logging performance before each job.

- The high-speed telemetry cartridge―which includes the casing-collar locator and accelerometer―enables compatibility with other Weatherford production-logging and cement-evaluation tools.

Tool Description

The Weatherford Raptor 2.0 cased-hole evaluation tool is a pulsed-neutron wireline logging device that provides advanced analysis of oil, water, and gas saturation behind the casing. The Raptor 2.0 cased-hole evaluation tool uses enhanced sigma and C/O techniques for oil-water saturation measurements in saltwater and freshwater formations. It uses a proprietary N-Vision technique to quantify gas-liquid saturation.

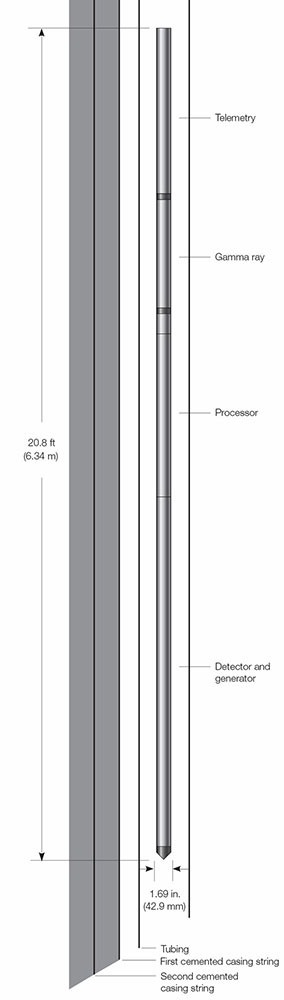

The Raptor 2.0 tool consists of a pulsed neutron generator, four spectroscopic lanthanum-bromide (LaBr3) detectors, a fast-neutron counter, and processing, control, and telemetry electronics. The telemetry cartridge includes the casing-collar locator. The addition of a gamma ray, pressure, and temperature sub completes the standard operational configuration.

The Raptor 2.0 tool is suited for formation evaluation, production logging, and well integrity measurements. For formation evaluation, the tool has three different data-acquisition modes (sigma, C/O, or N-Vision) to suit the logging objective. The Raptor 2.0 tool probes the formation with pulsed high-energy neutrons. During neutron-nuclei interactions, the neutrons are scattered (inelastic reactions), slowed (elastic), and absorbed (capture). The tool detects the resulting gamma radiation, which is analyzed to yield formation and fluid information.

For production logging and well integrity operations, the detected radiation is a result of momentary activation of oxygen in water, which is produced by high-energy neutrons. This brief radioactivity helps to determine the velocity and direction of water flowing inside and outside the casing.

Specifications

Measurement

Data | Sigma, C/O, inelastic, capture-count rates, and spectroscopy measurements |

Logging speed | Sigma mode: 20 ft/min (6 m/min) |

Measurement range | 0 to 60 capture units |

Vertical resolution | 12 in. (304.8 mm) |

Accuracy | ±0.25 capture units |

Depth of investigation | 7.6 to 15.8 in. (193 to 401.3 mm) |

Borehole fluids | Saltwater, freshwater, oil, gas, water-base mud, oil-base mud, and completion fluid |

Mechanical

Outer diameter | 1.69 in. (42.90 mm) |

Length | 20.8 ft (6.34 m) |

Weight (air) | 95 lb (43 kg) |

Maximum temperature | 300°F (150°C) |

Maximum pressure | 20,000 psi (137.9 MPa) |

Maximum borehole diameter | 18 in. (460 mm) |

Minimum borehole diameter | 2 in. (50.8 mm) |

Reach out to optimize reservoir performance

Please fill in the form below for more information on our comprehensive and high-resolution technologies. You will hear from one of our wireline representatives shortly.

Thank you for contacting us.

Your request is being directed to the appropriate person in our organization.

We will be in touch soon.