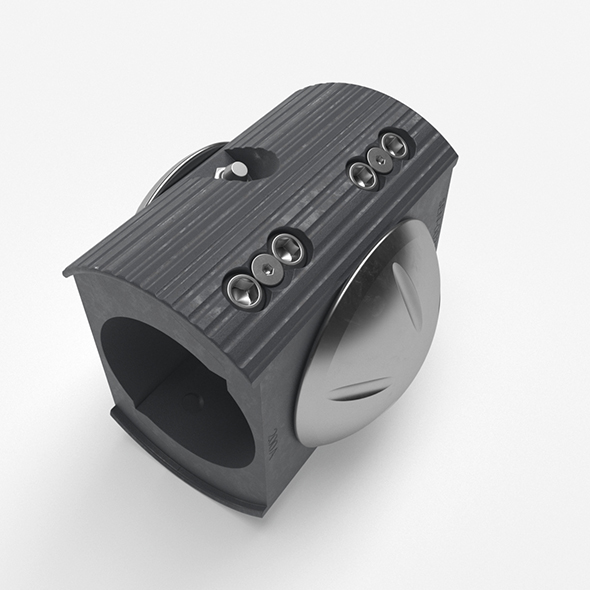

Cased-Hole I-Wheel®

Provides lift and reduces contact with the wellbore

Applications

- Cased-hole

Perforating

Features and Benefits

- Provides lift and reduces contact with the wellbore

- Creates standoff via free spinning and self-orienting design that drastically reduces the risk of differential sticking

- Free spinning and self-orienting assist deployment

Tool Description

The Weatherford cased-hole I-Wheel creates low contact areas that keep the tool body off the low side of the bore wall, with a gap to pass over problem areas. They can be placed anywhere along the toolstring and are efficient, consistent, and reliable tools in highly deviated wells up to 84° and reduce modelled friction by up to 80%.

Cased-hole I-Wheels are routinely used to convey perforating guns. They can be placed above, below, or between gun sections, with the detonating cord run through the mandrel. They allow the gun to rotate independently of the wheels, assisting on the orientation of shot in high-or low side perforating.

A wide range-of I-Wheel designs are available for any tubing, casing, or borehole size. Optional in-line or over-body-variants enable the best tool configuration for optimum deployment. Custom-engineered sizing and bespoke mounting variants are developed upon request to suit specific applications and well conditions.

Specifications

Environmental

Maximum temperature | 450°F (232°C) |

Maximum pressure | 25,000 psi (172 MPa) |

Material hub/wheel | 17-4 PH/H1150 Stainless Steel |

Mechanical

I-Wheel hub OD | Hub makeup length | Tubing/casing range |

1.5 in. (38 mm) | 1.7 in. (44 mm) | I-Wheels range from 2-3/8 in. tubing up to 7 in. casing |

1.69 in. (43 mm) | 2.5 in. (63 mm) | |

2.0 in. (51 mm) | 3.1 in. (80 mm) | |

2.875 in. (73 mm) | 3.4 in. (87 mm) | |

| FIX SIZE 3.375 in. (86 mm) | 3.6 in. (92 m) | |

| 4.5 in. (114 mm) | 4.2 in. (107 mm) |

Accessories: Perforating Gun Available Sizes

Gun OD | Gun makeup length |

2.0 in. (51 mm) | Varies depending on customer requirements |

2.75 in. (70 mm) | |

| 2.875 in. (73 mm) | |

| 3.125 in. (79 mm) | |

| 3.375 in. (86 mm) | |

| 3.50 in. (89 mm) | |

| 4.50 in. 114 mm) |

Accessories: E-line Sub Available Sizes*

Sub OD | Sub makeup length |

1.5 in. (51≥ mm) | Slipover Sleeves attach onto the toolstring which reduces toolstring length |

1.69 in. (43 mm) | |

| 2.0 in. (51 mm) | |

| 2.125 in. (73 mm) | |

| 2.50 in. (64 mm) | |

| 2.75 in. (70 mm) | |

| 2.875 in. (73 mm) | |

| 3.125 in. (79 mm) | |

| 3.375 in. (51 mm) | |

| 3.5 in. (89 mm) | |

| 3.625 in. (92 mm) | |

| 3.875 in. (98 mm) | |

| 4.0 in. (102 mm) | |

| 4.5 in. (114 mm) |

*Connections to suit customer requirements.

Accessories: Slipover Sleeve Available Sizes

Tool OD | Makeup length (N/A) |

1.5 in. (38 mm) | Slipover Sleeves attach onto the toolstring which reduces toolstring length |

1.69 in. (43 mm) | |

| 2.0 in. (51 mm) | |

| 2.125 in. (73 mm) | |

| 2.50 in. (64 mm) | |

| 2.75 in. (70 mm) | |

| 2.875 in. (73 mm) |

Reach out to optimize reservoir performance

Please fill in the form below for more information on our comprehensive and high-resolution technologies. You will hear from one of our wireline representatives shortly.

Thank you for contacting us.

Your request is being directed to the appropriate person in our organization.

We will be in touch soon.