Compact™ Microimager Tool

Delivers high-definition, fullbore images in conductive muds

Applications

- Visualizing complex structures

- Identifying faults and fractures and their orientation

- Determining structural dip

- Defining crossbeds, thin beds, and net-to-gross ratio in sand-shale sequences

- Identifying sand-shale facies and sand counts

- Evaluating secondary porosity

- Depth-matching, orientation and substitution of cores, structural and breakout analysis, and true vertical depth (TVD) analysis

Features and Benefits

- Eight pads with 176 measurement electrodes and excellent dynamic range measurement electronics deliver accurate microresistivity measurements and detailed, fullbore images.

- Two offset, four-arm caliper mechanisms maintain pad contact and provide six independent caliper readings. The upper calipers provide tool centralization while the lower calipers act independently.

- Onboard flash memory stores high-resolution images in the time domain, independently from data logged via wireline.

- The tool is compatible with Reveal 360° image processing, a digital imaging technology that uses microresistivity measurements to deliver a complete 360° view.

- For thru-drillpipe applications or wells with small borehole, the tool can be configured with pads for a maximum OD of 2.4 in. (61 mm).

- The tool can be configured without pads as a multi-arm caliper tool.

Tool Description

The Compact microimager (CMI) provides high-quality formation images in water-based muds. The excellent borehole coverage and high-resolution imaging capabilities of the CMI enable enhanced reservoir characterization for more informed reservoir decisions.

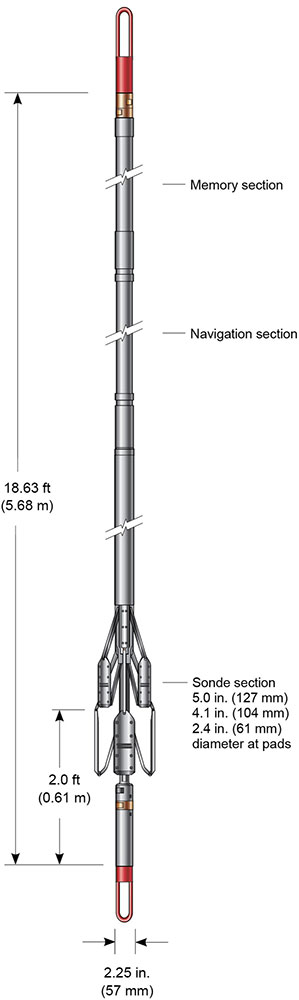

The CMI consists of a memory section (MIM) and a measurement section (MIE). High-resolution, time-based data is recorded into the MIM while 3.937-in. (10-cm) log quality control data is transmitted to the surface. This tool can be run in multiple configurations for use in diverse applications.

Specifications

Measurement

Data | Microresistivity imaging, borehole geometry, and multi-arm caliper |

Logging speed | 2,000 ft/hr (10 m/min) |

Vertical microresistivity resolution | 0.2 in. (5 mm) |

Accuracy | Caliper: ± 0.2 in. (5 mm) |

Depth of investigation | 0.90 in. (23 mm) nominal for microresistivity |

Measurement range | Tilt: 0° to 180° |

Borehole fluids | WBM, salt |

Mechanical

Tool | CMI 5.0 | CMI 4.1 | CMI 2.4 |

Maximum outer diameter | 5.0 (127 mm) | 4.10 in. (104 mm) | 2.40 in. (61 mm) |

Length | 18.63 ft (5.68 m) | ||

Weight (air) | 126 lb (57.2 kg) | ||

Maximum temperature | 320°F (160°C) | 300°F (150°C) | |

Maximum pressure | 15,000 psi (103 MPa) | ||

Maximum borehole diameter | 17.0 in. (432 mm) | 12.25 in. (311 mm) | 11.6 in. (295 mm) |

Minimum borehole diameter | 5.5 in. (140 mm) | 4.6 in. (117 mm) | 2.9 in. (74 mm) |

The Compact microimager (CMI) tool is available in multiple sizes and configurations for use in diverse applications.

Reach out to optimize reservoir performance

Please fill in the form below for more information on our comprehensive and high-resolution technologies. You will hear from one of our wireline representatives shortly.

Thank you for contacting us.

Your request is being directed to the appropriate person in our organization.

We will be in touch soon.