CalView® Tool

Captures a high-resolution casing profile with 60 independent arms that expand from 6 to 16 in. (152.4 to 406.4 mm)

Applications

- Monitoring internal casing corrosion or scale buildup

- Evaluating drilling wear

- Inspecting marine risers and deepwater casing

- Identifying split, parted, or deformed casing

- Evaluating pipe deformation caused by geomechanical stresses

- Analyzing axis deformation, clearance circle, and ovality

Features and Benefits

- Captures data from multiple casing sizes in a single run using 60 independent arms that expand from 6 to 16 in. (152.4 to 406.4 mm)

- Delivers high-resolution measurements with an array of caliper arms and independent radii measurements

- Enables advanced cross-sectional analysis that enhances geomechanical deformation interpretation through use of an eccentricity algorithm and onboard inclinometer package

- Produces graphical cross-sectional and 3D plots of casing ID for easy identification of anomalies and advanced interpretation of deformation after processing through TVision software

- Highlights sources of fluid entry to support the identification of casing anomalies through use of a temperature sensor

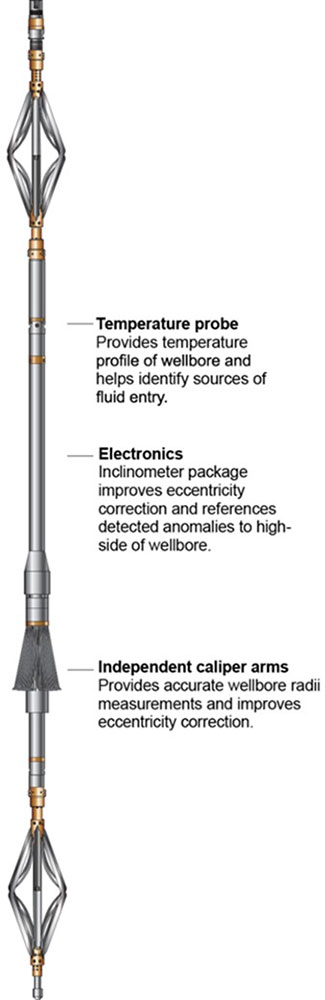

Tool Description

The Weatherford extended-range, 60-arm CalView tool provides an accurate internal casing profile from an array of precision-calibrated feeler arms. Each arm provides independent radial measurements that identify drilling wear, corrosion, scale buildup, splitting, buckling, and deformations caused by geomechanical stresses.

Operators can monitor tool response in real time, which enables multiple passes over anomalous features on the casing profile. The long arms deliver measurements in casing IDs from 6.25 to 16 in. (158.8 to 406.4 mm) in a single run while maintaining high accuracy and resolution. Rated to 30,000 psi (206.8 MPa), the tool also can be used to analyze casing deformation and bending through use of an eccentricity algorithm and onboard inclinometer package.

Tool data is exported to Weatherford TVision analysis software, which classifies each casing joint with respect to the worst-case defect found and joint-by-joint well summary. The analysis package can also graphically portray the casing as a 2D cross section or 3D image to highlight anomalies.

Specifications

Measurement

Data | Radii, well temperature, and deviation |

Maximum logging speed | 4,800 ft/hr (1,460 m/hr) |

Recommended logging speed | 2,400 ft/hr (730 m/hr) |

Vertical resolution | 1.0 in (25 mm) |

Radial resolution | 0.005 in. (0.127 mm) |

Accuracy | ±0.08 in. (±2.03 mm) |

Borehole fluids | WBM, OBM, salt, air |

Mechanical

Tool diameter | 6 in. (152.4 mm) |

Tool weight | 227 lb (103 kg) |

Tool length | 94.34 in (2,396 mm) |

Caliper arms | 60 |

Casing ID range | 6.25 to 16 in. (158.8 to 406 mm) |

Pressure rating | 30,000 psi (207 MPa) |

Temperature rating | 350°F (177°C) |

Available answer products | TVision analysis 3D, TVision section analysis, BP, drift diameter analysis, casing joint summary analysis |

With an array of precision-calibrated feeler arms, the CalView tool captures data samples at ten times the industry standard rate.

Reach out to optimize reservoir performance

Please fill in the form below for more information on our comprehensive and high-resolution technologies. You will hear from one of our wireline representatives shortly.

Thank you for contacting us.

Your request is being directed to the appropriate person in our organization.

We will be in touch soon.