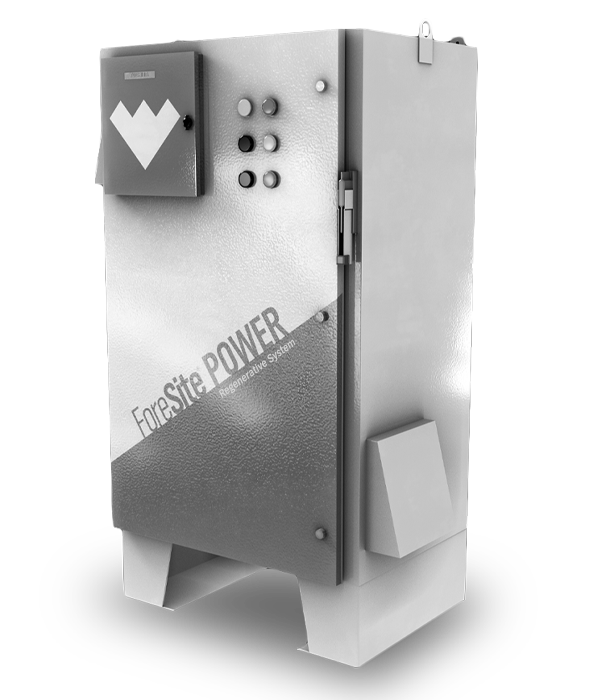

Power Regenerative System

Advanced VSD Energy Efficiency

ForeSite® Power Regenerative System is the energy industry’s first regenerative variable-speed drive (VSD) for rod-lift systems, featuring its seamlessly integrated power-management technology. Due to its unique ability to recycle, store, and optimize power, this innovative solution helps control operating expenses while reducing carbon emissions for the ultimate ecofriendly alternative to conventional VSDs and regenerative energy systems*.

*Potential tax rebates/incentives available through energy reductions if applicable.

Powerful Versatility

ForeSite Power Regenerative System technology is highly versatile as a retrofit solution and is compatible with traditional VSDs on existing wells. It even works seamlessly with standalone power generators, making it ideal for remote operations with solar-power access or even areas with no power grid.

Next-Generation Innovation

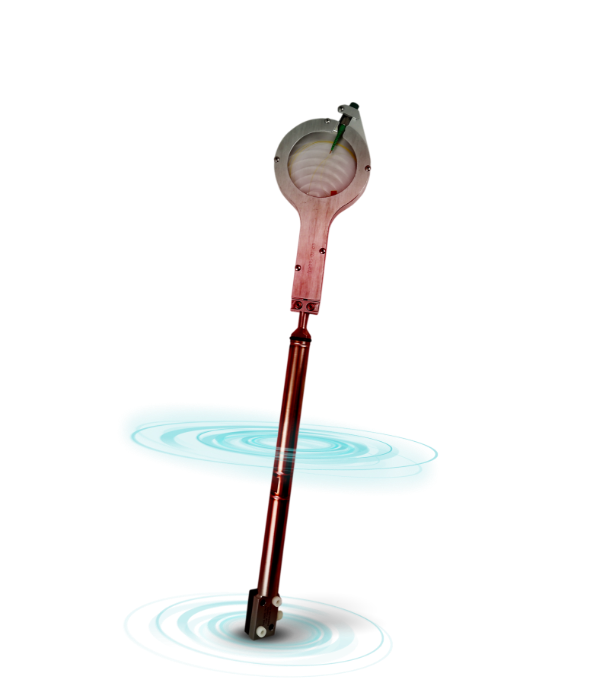

ForeSite Power Regenerative System takes regenerative energy to new levels exceptional of efficiency with its innovative power-storing capability—transforming potential energy from the rod-lift system back into electrical energy. This productive power is then converted to reduce kilowatt-hour (kWh) consumption and enhance efficiency. The system cleverly re-captures energy that would otherwise go to waste as heat. Welcome to the next generation of advanced VSD energy efficiency.

Reduce

PRODUCTION COST

Boost ROI with superior energy-infrastructure utilization and up to 3X power savings*. Reduce energy consumption and related emissions through conversions of potential energy into electrical energy. This translates to more than $500 savings per well, per month**.

Regenerative Energy Production

Reduce reliance on the power grid for increased efficiency and significantly decreased kWh consumption. Minimize carbon footprint and unlock up to three times more energy savings compared to conventional regenerative VSDs**.

Capacitor-Based Storage

Capture and reuse regenerated rod-lift energy for reduced kWh usage and minimized peak demand—typically reducing power consumption requirements from utilities between 15 to 30 percent**.

Integrated Power Management

Eliminate additional installation costs with unified VSD technology that combines onsite power storage with the electrical ride-through system—avoiding the additional land or grid infrastructures typically required by solar and wind power**.

Adaptable Design

Convert any rod-lift system outfitted with versatile power-management technology including all VSD systems and standalone power generators—ideal for remote operations with no power-grid access.

Empower

NET-ZERO INNOVATION

Save energy and reduce emissions to improve overall ESG ratings and achieve carbon-neutral goals by lowering energy consumption used per barrels produced of oil equivalent (BOEs). Maintain production rates and bottom-line profits with ideal operational efficiencies that improve MTBFs and maintenance calls requiring heavy machinery and their excess carbon emissions.

Reclaimed Energy

Reduce carbon footprint and operating expenses by capturing energy traditionally lost by rod-lift downstrokes—for every one kWh reclaimed, 1.7 lbs of CO2 is eliminated or about 254 tons per year, or 55 cars driving 638,352 miles per year**.

Improved Environmental Profiles

Increase energy efficiency with aggregate and peak power reductions. Fieldwide applications improve energy, carbon, and waste environments for valuable ESG reports that help reduce lease operating expenses and improve production updates.

Carbon Rebates/Tax Incentives

Take advantage of state/federal benefits in countries where qualifications for CO2-reduction reimbursements apply. Qualify for federal investment tax credits and reduce strains on power grids by reducing demand during peak hours†.

DC Combiner

Unify DC busses from multiple VSDs per pad to positively impact ESG ratings and reduced carbon emissions.

Lower

OPEX COSTS

Reduce maintenance costs and enhance safety while improving overall production performance with supplemented AC power that saves up to 16% kWh consumption—creating a payback period of just 18-months††. Continuous voltage-monitoring also protects equipment from power spikes, fluctuating current demands, and challenging temperatures.

Reduced Braking Loads

Minimize DBR (dynamic-braking resistor) utilization for improved system performance, reduced upkeep, and extended MTBFs.

Weatherized Housing

Ensure safe and reliable outdoor operations featuring a NEMA 3R enclosure. Exclusive, marinized design is built for extreme reliability in all onshore environments and is compatible with any diode bridge front‐end drive.

Independent Circuitry

Isolated pre-charging systems complies with all UL requirements for added safety.

Production 4.0 Compatibility

Achieve asset-wide integrated production optimization with seamless digitalized automations from ForeSite platform and Production 4.0 integration technologies.

*Compared to conventional regenerative VSD

**Based on customer trials

†USA specific (including federal IRA incentives up to 22% (2023) and 10% (2024 onward))

††Typical kWh savings vary from ~12% to ~16%. Payback period reduced to 14 months with ITCs.

Field-Proven Performance

SAVED $9,792/WELL/YR

ENERGY COSTS AND CUT 103.3 TONS CO2/WELL/YRNORTH DAKOTA

- Unified 2 Rod-Lift Systems

- Cut Power Costs 15%-20%

- Increased Efficiency 74%

- Reduced Peak-Grid Reliance

- Achieved 18-Mo. Payoff

SAVED 16% KWH

USAGE AND

RECLAIMED 1.7 LBS CO2/KWHTEXAS

- Boosted Production Performance

- Reduced Peak-Grid Reliance

- Lowered Carbon Footprint

- Enhanced Safety

- Achieved 14-Mo. Payoff

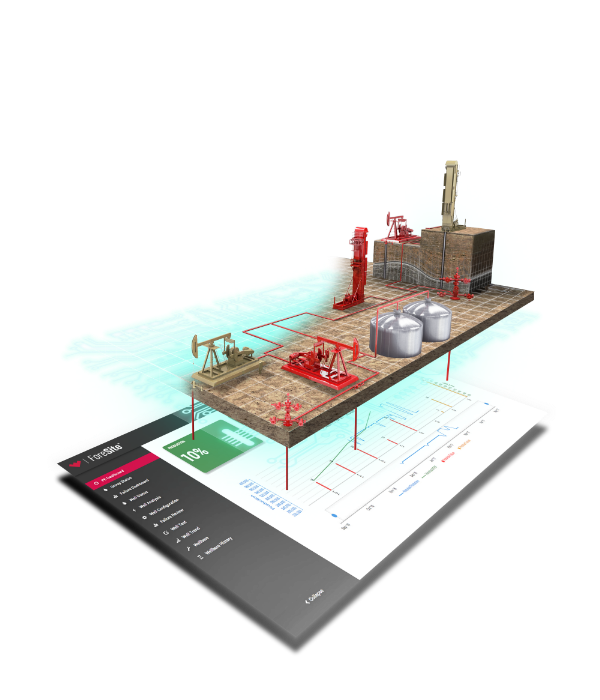

COMPLEMENTARY SOLUTIONS

FOR PRODUCTION 4.0

ForeSite®

Power

Power-up with advanced VSD energy efficiency

Discover Next-Generation VSD Efficiency

To learn more about integrated VSD power-management technology for rod-lift systems, simply complete the form below and a production specialist will contact you soon.

Thank you for contacting us.

Your request is being directed to the appropriate person in our organization.

We will be in touch soon.