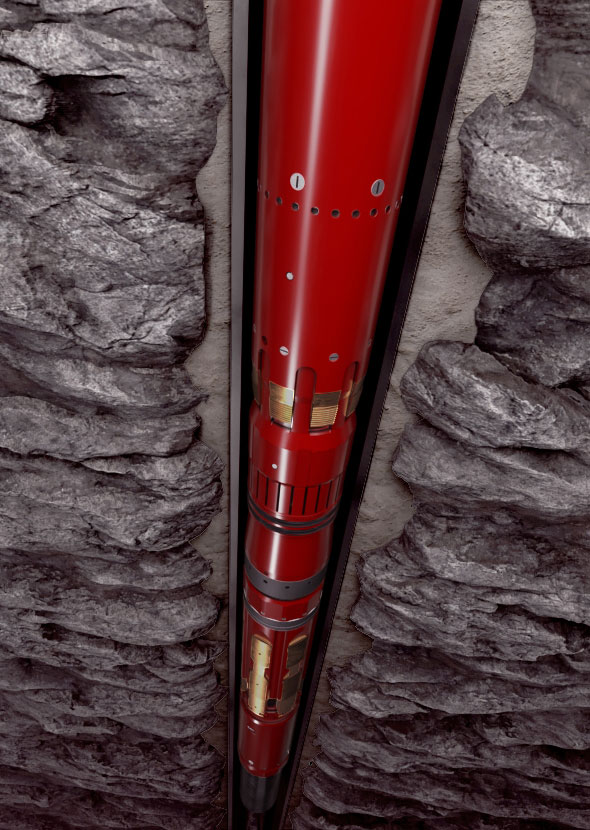

Xpress™ XT Pressure Balanced Liner System

Achieve secure-and-reliable well integrity, even in the most severe downhole environments

The Xpress XT pressure-balanced liner system integrates a high-performance liner hanger and a packer on a single-piece mandrel. This allows unrestricted pressures and flow rates during deployment – eliminating the possibility of presetting the liner hanger or premature release of the running tool. Xpress XT de-risks liner installations with its unique setting mechanism that maintains a pressure-balanced environment throughout deployment, even in the most challenging well conditions. Xpress XT is ideal for all liner-system installations, including HPHT, drill-down, ream-down, extended-reach, and floating-liner operations.

Precision Deployment

Enables low-risk installations and reliable depth-placement

Surge-resistant system withstands high-pressure circulation and sudden pressure changes to prevent premature setting of hanger or release of running tool during installation.

Maintains a pressure-balanced environment during the installation process. The system-design tolerates use of lost-circulation material (LCM) during deployment.

Permit ream-down capability with 50,000 ft-lbs of torque at the liner top.

Prevents pre-setting of liner-top packer and liner hanger during run-in hole operations.

Prevents debris from entering the liner system during deployment.

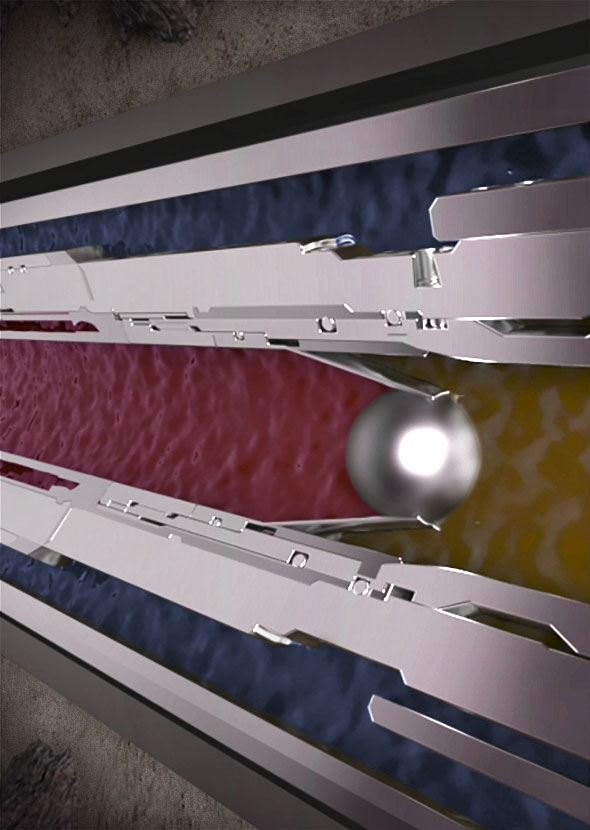

Single-Trip Liner Setting

Provides simplified hanger activation and time-saving efficiency

Single ball-drop activation of pressure-balanced R-type running tool and retrievable seal mandrel reduces installation time for fast activation and cement placement.

Allow setting in the toughest environments.

Ensures recovery of running tools.

Provides enhanced cement placement.

Ensures accurate cement displacement.

Life-of-Well Performance

Provides long-term well integrity and reliability

API 19LH, VS1 rating holds strong at temperatures up to 400°F (204°C) and pressures up to 10,000 psi (68.94 MPa) for downhole reliability and life-of-well performance.

Meets API 19LH VS1 test criteria. Pressure and temperature reversals with combined loading of liner hanger and packer with PBR interface and tie-back validations rated to 10,000 psi, 150° to 400°F (66° to 204°C).

Elastomers, weight ranges, and threads configured to unique well environment for long-lasting durability.

Eliminates internal connections and removes the risk of associated connection leaks for improved production performance.

Include hanging- and hold-down capacities for long-term operational requirements.