ESS® Expandable Sand Screens

More production, faster ROI, reduced CO2

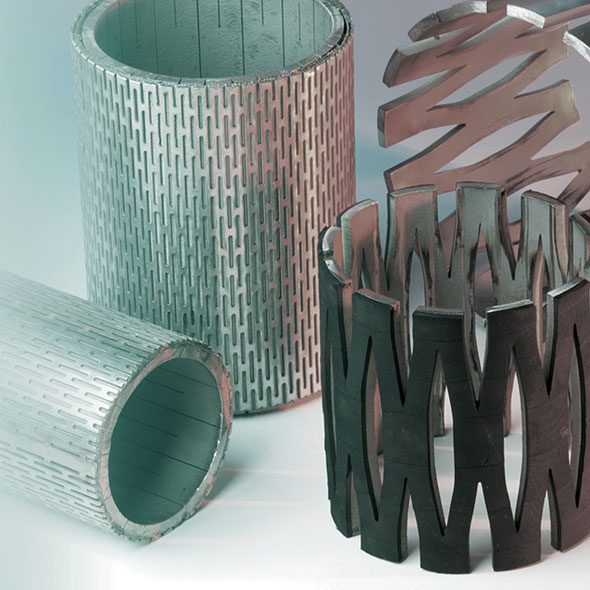

From the leader in trusted, sand-screen expertise, the field-proven ESS screens manage particulates that hinder production and damage downhole and surface equipment. This exclusive solution enhances production and efficiency with its simplified deployment and expansion technology delivering faster, greater ROIs as well as reduced CO2 emissions. ESS screens are ideal for challenging reservoirs with non-uniform or poorly consolidated formations where problematic sands can result in sand-control-equipment failure, productivity decline, and premature well abandonment.

Once expanded, this system mitigates the risk of sand production through removal of the screen-to-formation annulus while stabilizing the near-wellbore formation. This provides added borehole support and sand exclusion without gravel-pack filtration.

ESS expandable sand screens are part of a modular, expandable completion-system designed for maximizing reservoir productivity and minimizing OPEX. Sand screen sections are selectively deployed to control transfer of reservoir solids to the wellbore, optimizing productivity, reliability, and efficiency.

Streamline Deployments

Simplified installation technology reduces rig days, saves OPEX, and starts producing faster. Advanced deployment efficiencies reduce installation costs to achieve greater, faster ROIs. Save on fewer personnel requirements and surface- equipment needs such as pumping units, mixers, and high-pressure lines.

- Fast and efficient installation requires only standard rig equipment, saving CAPEX and OPEX by reducing rig time and enhancing uptime.

- Exclusive design applicable to a wide range of applications and features a high surface area inflow filter for maximized sand retention

- Expandable zonal isolation joints can be included to packoff the wellbore annulus, providing reliable, openhole isolation across multiple payzones.

Increase Productivity

Compliant wellbore contact delivers sand retention, performance reliability, and bottom-line results. The screen-to-wellbore contact provides a low skin completion, superior productivity index, and minimum required drawdown for enhanced production and faster ROI.

- Expansion eliminates the annulus and supports the load-bearing sand grains to form a stable arch for reliable sand control and prevention of failed mud cake and reservoir sand mixing at the screen surface.

- Expanded screen inner diameter provides increased flow area while reducing flowing friction pressures that contribute to gas/water coning affects.

- Large, expanded base pipe inflow area provides direct access to filter media, enabling filter cake treatment and efficient near wellbore cleanup.

Reduced Carbon Footprint

Enhanced efficiencies reduce rig days, producing less CO2 emissions. Radial-expansion technology eliminates conventional gravel-pack filtration and its associated surface equipment—reducing carbon emissions and related HSE risks.

- Well site mobilization of expandable sand screen completion configurations is logistically simple and straight forward. Reducing the associated carbon footprint and is well suited to remote location requirements.

- Efficient operations improve safety by removing high-pressure lines, heavy lifting, and hazardous machinery required by conventional systems.