MARS Mature Asset Rejuvenation by Surveillance System

Instant insight to extend the life of the asset

Optimizing mature wells relies on the essential component of reservoir intelligence in real time. The Weatherford MARS Mature Asset Rejuvenation by Surveillance system is the energy industry’s most advanced thru-tubing intervention and reservoir-data solution.

MARS offers a cost-effective imaging solution that spans the full length of any well, enabling the enhancement of mature-well reservoirs. The field-proven flexibility establishes an all-in-one reservoir-surveillance system, ensuring a continuous stream of actionable well data for critical management and decision-making. MARS decreases production costs in operational wells by precisely positioning fluids, maximizing performance at production intakes throughout the entire reservoir. Data visualization software then presents data via its specialized dashboard, offering live remote access and transmissions through iOS/Android applications on the cloud.

![]()

Advanced Real-Time Well Management

![]()

Enhanced Remedial Intervention

![]()

Streamlined Deployment Flexibility

Advanced Real-Time Well Management

Improved monitoring capabilities offer uninterrupted, high-resolution data along the entire wellbore, optimizing production and facilitating effective reservoir management across various production environments.

Integrated DAS, DTS, and P/T sensors

Provides real-time well conditions during critical operations and monitoring campaigns to support proactive decision making for improved strategies and unparalleled efficiency.

Multiphase flowmeter with NIR sensitivity

Instantly distinguishes between water, oil, methanol, and glycol in the full range (0%-100%) of water cut and full-range of gas-void fraction (GVF)—regardless of salinity, chemistry, solids, impurities, H2S, CO2, emulsions, and polymers.

Remote data streaming

Instant data modeling provides secure visual diagnostic transfers, regardless of bandwidth.

Thousands of wellbore sensors

Provide continuous temperature profiles and acoustic signatures that eliminate unmonitored areas for precision leak detection, sand control, lift optimization, and waterflood management.

Non-intrusive venturi-affect sonar

Surrounds casing to accurately measure oil and gas flow and gas-liquid ratios by sensing turbulent fluid moving from one sonar sensor to another for readings that are unaffected by flow regimes or slugging.

Enhanced Remedial Intervention

Real-time well intelligence data enables proactive remediation of challenges for rigless intervention efficiency at any operational stage.

Non-nuclear flow measurements

Provides ultra-precise, full-range, multiphase support redundancy for any fluid mixture—eliminating dedicated separator equipment, frequent human interventions, and onsite calibrations for up to 70% less operation expense.

Target detection

Identifies corrosion, scale, casing wear, collar leaks, cased-hole integrity, and injectivity performance—improving communication analysis for hydraulic fracturing, including stimulation and waterflood operations.

Wellsite visualization and interpretation

Analysis provides intelligence for flow allocation, production optimization, in-flow profiling, production modeling, and precision reservoir-management strategies.

Advanced visualization and data interpretation

Display time and depth, synchronized DAS and DTS data, as well as MPFM data incorporations from any sensor point for ultra-precise and fast analysis.

Streamlined Deployment Flexibility

Rigless operations and reduced footprint delivers well intelligence across the reservoir. This provides tailored monitor/intervention periods for the ultimate in streamlined operations, reduced OPEX, and decreased environmental impact.

Fiber line intervention

Provides advanced monitoring in challenging wells with up to 80-degree deviations via extended reach, fiber-deployed installations for advanced flexibility that provides low upfront costs while eliminating the CAPEX requirements.

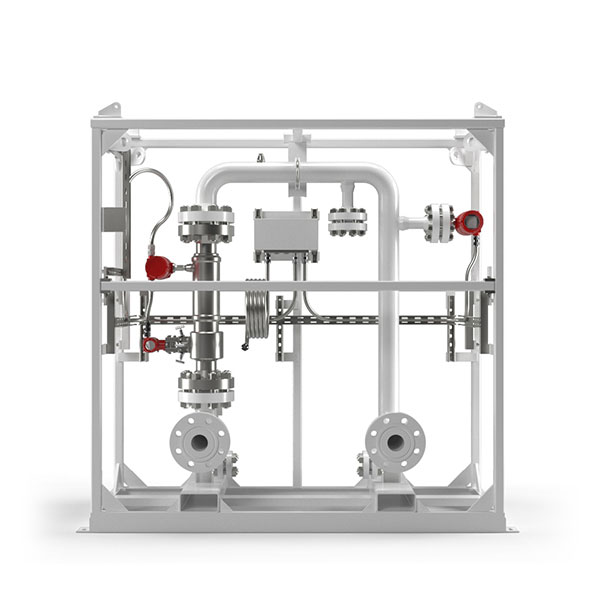

Skid- or truck-mounted deployment

Modular and mobile compatibility for offshore/satellite installations and wellsites is ideal for temporary interventions, eliminating the need for permanent fiber-optic monitoring systems.

Easy-to-deploy, rigless conveyance

Simplifies installation with single fiberline that reaches deeper, more-deviated wells, compared to conventional systems—enabling access to any type of well and minimized HSE risk and redzone exposure.

Small footprint

Improves location safety with smaller redzones that are ideal for remote, offshore, or confined locations including platforms with lifting limitations*.

*Max lift under 3,000 kg for light modular units.

High-endurance fiber-optic lines

Ideal for deep geothermal applications and challenging wells up to 300°C.

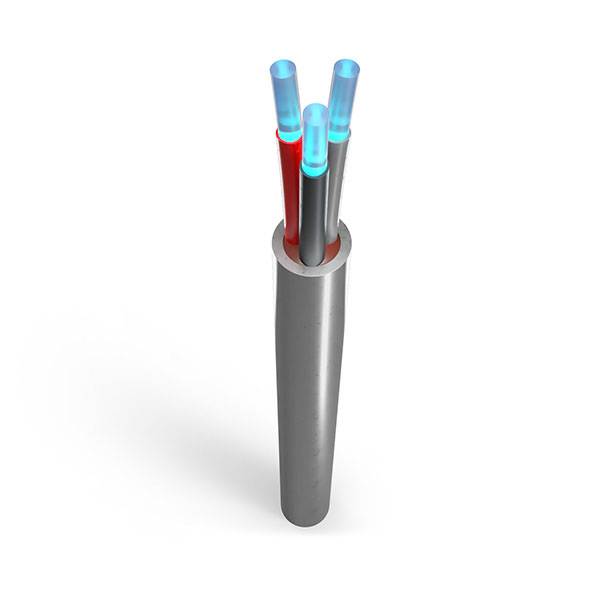

Optical Pressure and Temperature (P/T) Sensor

Comprehensive, multiparameter downhole sensing for well production, injection, storage, and monitoring. These sensors can be combined with multiple MARS components or other optical sensors to tackle the most challenging well conditions.

Fiber Line

Quickly monitor wellbore conditions and prevent equipment failures with efficient, high-speed fiber-optic data transmission. With up to four single- or multi-mode fibers in any combination, DTS and DAS is supported while wellbore activity is monitored across the entire length of the fiber line.

Multiphase Flowmeter (MPFM)*

Full-range, non-nuclear multiphase flowmeter that delivers critical flow-data intelligence with non-nuclear simplicity. By eliminating the gamma densitometer, restrictions, costs, and HSE risks are significantly reduced.

*Optional

Extend the Lifespan of Production Through Real-Time Reservoir Data

Experience the all-in-one reservoir-surveillance solution for your mature well. Contact our experts to learn more.

Thank you for contacting us.

Your request is being directed to the appropriate person in our organization.

We will be in touch soon.