Memory Raptor® Cased-Hole Evaluation System

Reveals bypassed reserves with accurate through-casing reservoir characterization

Applications

- Monitors changes in reservoir fluid saturation for optimal production management

- Determines hydrocarbon type and saturation

- Locates reservoir fluid contacts

- Identifies bypassed reserves in producing wells

- Performs production diagnostics

Features and Benefits

- The Memory Raptor system delivers advanced pulsed-neutron measurements in all modes with data that is identical to that from conventional wireline operations, eliminating the need to mobilize, transport, and install a full-service wireline unit.

- Services are performed by a single engineer using a small, lightweight slickline deployment package, reducing operational complexity and enabling efficient, cost-effective operations for mature offshore assets.

- A large array of four spectroscopic detectors increases gas-measurement sensitivity by about 250% compared to traditional two-detector tools, delivering multiple regions of investigation for accurate results in complex completion environments.

- The system lowers health, safety, and environmental (HSE) impact through reductions in risk exposure, energy, emissions, and waste:

- Smaller vessels may be used for marine transportation, saving energy and reducing emissions and waste

- Fewer crane operations are required, reducing risks and lowering energy and emissions

- One-person crew requires fewer resources aboard the platform

- The reservoir data extends the life and improves the production of existing wells, requiring fewer new wells to produce the asset

Tool Description

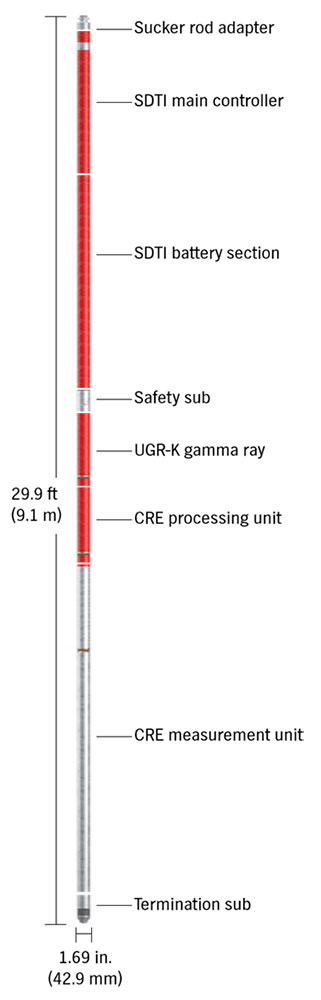

The Memory Raptor cased-hole evaluation system is a pulsed neutron wireline-logging device that provides advanced analysis of oil, water, and gas saturation behind casing. The Raptor system consists of a pulsed neutron generator, an array of four spectroscopic lanthanum-bromide (LaBr3) gamma ray detectors, a fast-neutron counter, and processing, control, and telemetry electronics. It has two physical sections: the measurement (CRM) unit that contains the detectors and generator, and the processing (CRP) unit that contains the processing and control electronics.

The system probes the formation with bursts of high-energy neutrons emitted by the neutron generator. During interactions with the nuclei of elements in the formation, the neutrons are scattered (inelastic reactions) and absorbed (capture reactions). The Raptor system detects the gamma radiation resulting from these inelastic and capture interactions, which is analyzed to yield information about the formation and its fluids. For formation evaluation, the system has three data-acquisition modes—Sigma, carbon/oxygen (C/O), and N-Vision—to suit the logging objective.

The Memory Raptor system adds a memory and battery controller and a safety sub to provide completely autonomous control of the data acquisition so that it can be run in memory mode. The memory and battery controller, known as the Smart Downhole Tool Interface (SDTI), provides the same acquisition functions that would be provided by the surface system electronics, logging software, and Field Engineer in a conventional wireline operation. These SDTI tasks include programming of the logging sequence, system power, generator control, pulse timing, spectral stabilization, detector gain control, data storage, and safety functions. All modes are available in memory, and the data is identical to that from conventional wireline logging acquisition.

Specifications

Measurement

Data | Sigma, C/O, inelastic and capture-count rates, and spectroscopy measurements from the proximal, near, far, and long detectors |

Logging speed | Sigma mode: 15 to 30 ft/min (4.6 to 9.1 m/min) |

C/O mode: 2 to 3 ft/min (0.6 to 0.9 m/min) | |

N-Vision mode: 8 to 10 ft/min (2.4 to 3.0 m/min) | |

Measurement range | 0 to 60 capture units |

Vertical resolution | 12 in. (304.8 mm) |

Accuracy | ±0.25 capture units |

Depth of investigation | 7.6 to 15.8 in. (193 to 401.3 mm) |

Operation modes | Sigma, carbon/oxygen, N-Vision |

Borehole fluids | Salt water, fresh water, oil, gas, water-based and oil-based drilling and completion fluids |

Mechanical

Outer diameter | 1.688 in. (42.9 mm) |

Length | 29.9 ft (9.1 m) |

Total weight (in air) | 157 lb (70.8 kg) |

Maximum temperature | 302°F (150°C) |

Maximum pressure | 15,000 psi (103.4 MPa) |

Maximum borehole diameter | 18 in. (460 mm) |

Minimum borehole diameter | 1.995 in. (50.7 mm) |

Battery life | 20 hours |

Memory | 16 Gb (> 20 hours recording capacity) |

Reach out to optimize reservoir performance

Please fill in the form below for more information on our comprehensive and high-resolution technologies. You will hear from one of our wireline representatives shortly.

Thank you for contacting us.

Your request is being directed to the appropriate person in our organization.

We will be in touch soon.